The compressor provided by Xinjinhua for Hualu Hengsheng Jingzhou Base Project was successfully tested on site.

2024-02-29

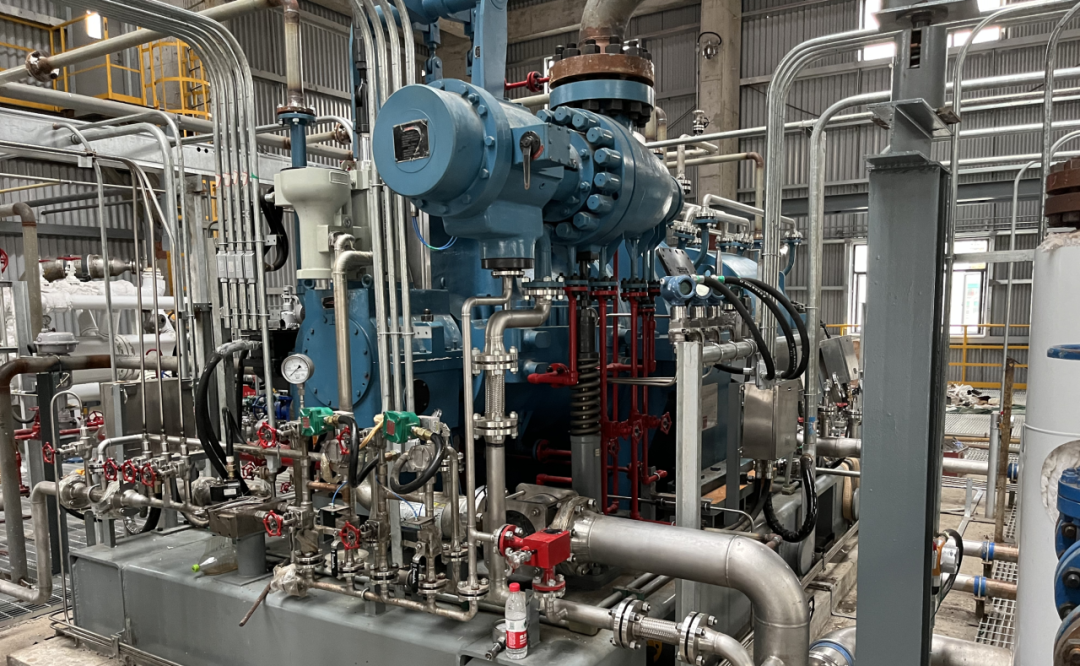

Recently, the synthesis gas compressor unit and carbon dioxide compressor unit provided by Xinjinhua for the first phase of Hualu Hengsheng Jingzhou Base Project were successfully tested on the installation site. The unit was stable in operation and had good parameters. Users highly praised it. The success of the test run means that the compressor unit of the project will officially enter the countdown to start-up, which is a big step closer to the goal of production. Since the cooperation, the company has provided more than 20 sets of units for Hualu Hengsheng. The successful test run of the units has proved that the company's advanced and reliable equipment and professional and efficient team service have once again been recognized by customers! Lay the company's leading position in the ammonia industry.

Hualu Hengsheng Jingzhou Base Syngas Comprehensive Utilization Project uses crude syngas from the gas power platform in the park as raw material to produce downstream products. Our company provides the core equipment in the production process: two sets of synthesis gas compressor units and two sets of carbon dioxide compressor units, which are mainly divided into two product chains. One is to produce synthetic ammonia from crude synthesis gas and urea from liquid ammonia and CO2. The second is to produce acetic acid and N,N-dimethylformamide (DMF) from crude synthesis gas. At the same time, by-products monomethylamine, trimethylamine, sulfur and food grade CO2. After the first phase of the Jingzhou base project is put into operation, 1 million tons/year urea, 1 million tons/year acetic acid, 150000 tons/year and DMF 150000 tons/year mixed methylamine production capacity will be formed.

Brief Introduction of Hualu Hengsheng Jingzhou Base Project

The planned total investment of Hualu Hengsheng Jingzhou Base Project is 46 billion yuan, of which the first phase will invest 12.3 billion yuan and cover an area of 2495 mu. It will mainly build a clean and efficient coal gasification platform and carry out deep processing of synthesis gas to form basic chemical raw materials such as ammonia, saturated monohydric alcohol, methylamine, DMF, acetic acid and functional fertilizer in advance. The project uses syngas to produce saturated monohydric alcohols. The total scale of saturated monohydric alcohol plant is 800000 tons/year. The refined saturated monohydric alcohols produced are mainly used as raw materials for acetic acid plants as well as DMF plants.

Hualu Hengsheng (Jingzhou) Co., Ltd. Syngas Comprehensive Utilization and Park Gas Power Platform Project is one of the key construction projects in Hubei Province, and it is also a Class A project of the company. It is planned to build Hualu Hengsheng Jingzhou Modern Coal Chemical Base in three phases. The first phase of the project is divided into two sub-projects: the gas power platform in the park and the synthesis gas comprehensive utilization platform, which mainly develops the clean and deep processing industry of coal. 2. Phase III project mainly produces high-end chemical new materials, fine chemicals and hydrogen energy products. After the completion of the project, it is of great significance to promote the chain development and integrated operation of the new energy and new materials industry in Jingzhou Jiangling.

Introduction of Xinjin Power Group

Xinjin Power is a high-tech, collectivized and international A- share listed company with a stock code of 300157. Its business is mainly divided into two major sectors: high-end equipment, oil and gas assets and services. The high-end equipment sector is mainly based on Jinzhou Xinjinhua Machinery Manufacturing Co., Ltd., and its main products are centrifugal compressors, industrial drive turbines and complete sets of equipment. It is responsible for providing complete sets of domestic system equipment for oil, natural gas, coal, chemical industry, air separation, green energy and other fields. The new Jinhua machine products are used in synthetic ammonia urea, methanol, natural gas pipeline long-distance transmission, booster stations, and gas storage., Petroleum refining, salt chemical and other sub-applications of high-end compressor market has a leading position. In the field of synthetic ammonia, it has created a number of domestic first sets of syngas compressors-steam turbines, filling the domestic gap. Its core technology has reached the international advanced level.

As the only domestic manufacturer with independent technology of compressors and steam turbines, Xinjinhua has rich and solid performance in the field of industrial drive steam turbines and power generation within 75 MW. The new Jinhua machine successfully entered the field of localization of ethylene three-machine equipment. The supercritical carbon dioxide cycle power generation test set designed and manufactured by it is the first set in China. The successful operation of this equipment has helped China stand at the forefront of the world's thermal power generation technology. With the continuous expansion of business, the new Jinhua machine has gradually covered green hydrogen, green ammonia, green alcohol integration, compressed carbon dioxide energy storage, hydrogen energy storage and transportation and other new energy core high-end equipment areas.

The leader of the new Jin power energy change, the carrier of the country's heavy weapon!

Recommend News

NEW JCM will be showcased at the 2025 ADIPEC

2025-11-03