Technological Innovation-Xinjin Chemical Machine Has the Production Capacity of Supercritical Carbon Dioxide Cycle Power Generation System-Carbon Dioxide Compressor Unit

2024-02-29

As early as December 8, 2021, Xinjinhua Machinery cooperated with China Huaneng Group Co., Ltd., and Huaneng Group led the world's highest parameter and largest capacity supercritical carbon dioxide cycle power generation test unit independently developed by multiple institutions in the United Nations. Huaneng Xi'an Thermal Engineering Institute successfully completed 72-hour trial operation, and all indicators of the system fully met the design requirements to achieve high-standard safe and stable operation. Our company independently develops and produces the supercritical carbon dioxide compressor unit, the core equipment of the system, with a design outlet pressure of 21.5MPA, reliable and efficient operation. The unit fills the gap in the domestic carbon dioxide power generation field, and the technology belongs to the international leading level. The power generation of the whole machine is 5MW and the maximum temperature is 600 ℃. It is currently the largest unit of the same type in the world. 100 percent of the core equipment for power generation is made in China, involving more than 400 patents, which is a world leader.

The world's first large-scale supercritical carbon dioxide

Cyclic power generation testing unit

The system boosts the recovered carbon dioxide to more than 20MPa through the high-efficiency and energy-saving compressor produced by our company, and then heats it to 600 ℃ by heat source to form high-temperature and high-pressure gas, which drives the gas turbine to rotate, converts heat energy into mechanical energy, and then drives the generator to generate electricity.

The successful operation of the project verifies the feasibility of the industrial operation of supercritical carbon dioxide cycle power generation technology, and is expected to completely change the traditional thermal power generation technology for more than 140 years with water vapor as the mainstream of power generation, marking that China has been in the world's leading level in the field of supercritical carbon dioxide cycle power generation technology, It provides an important path to further improve energy utilization efficiency and achieve the goal of "double carbon.

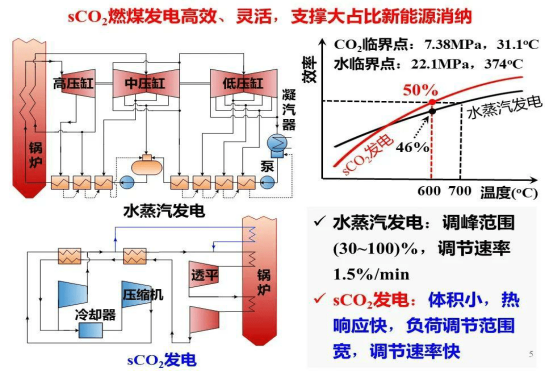

Supercritical carbon dioxide cycle power generation technology advantages

Supercritical carbon dioxide cycle power generation technology is an important transformative technology in the field of thermal power generation. Supercritical carbon dioxide is a very dense fluid, and higher density leads to higher transport efficiency. The generator set adopting this technology uses carbon dioxide as the circulating working medium. Compared with the traditional steam generator set, the carbon dioxide generator set has significant advantages such as high thermoelectric conversion efficiency, small volume of power equipment and system, and good flexibility. Under the same installed capacity, the length of its turbine main shaft is only 1/25 of that of the steam turbine, and 0-100% full load peak regulation can be realized. Under the condition of the main gas temperature of 600 ℃, the thermoelectric conversion efficiency is 3-5 percentage points higher than that of the steam unit.

Carbon dioxide cycle power generation technology will play a very important role in the consumption of new energy power. In the future, it will be further flexibly applied in thermal power, high-efficiency photothermal, nuclear power, energy storage and other fields to provide technical support for the construction of a new power system with new energy as the main body.

Thank you letter:

Introduction of Xinjin Power Group

Xinjin Power is a high-tech, collectivized, international A- share listed company, stock code: 300157. Its business is mainly divided into two major sectors: high-end equipment, oil and gas assets and services. The high-end equipment sector is mainly based on Jinzhou Xinjinhua Machinery Manufacturing Co., Ltd., and its main products are centrifugal compressors, industrial drive turbines and complete sets of equipment. It is responsible for providing complete sets of domestic system equipment for oil, natural gas, coal, chemical industry, air separation, green energy and other fields. The new Jinhua machine products are used in synthetic ammonia urea, methanol, natural gas pipeline long-distance transmission, booster stations, and gas storage., Petroleum refining, salt chemical and other sub-applications of high-end compressor market has a leading position. In the field of synthetic ammonia, it has created a number of domestic first sets of syngas compressors-steam turbines, filling the gap in the domestic market, and its core technology has reached the international advanced level.

Driven by the national "14th Five-Year Plan" energy development plan and the "30 · 60" dual-carbon target, Xinjin Power has conquered key core technologies through continuous technological research and development and technological innovation, enhanced its core competitiveness, and created more for users. Big value. At present, it has gradually covered the green hydrogen ammonia integration, green alcohol integration, carbon dioxide supercritical power generation, compressed carbon dioxide energy storage, air energy storage, hydrogen energy and other new energy core high-end equipment areas.

Xinjin Power unremittingly promotes green, low-carbon and high-quality development, creates more energy-saving and efficient equipment, helps the country achieve the goal of "double carbon", and continues to be the leader of energy reform and the bearer of the country's heavy equipment!

Recommend News

NEW JCM will be showcased at the 2025 ADIPEC

2025-11-03