NEW JCM Supports Successful Launch of Xinlianxin Chemical Industry Group Co., Ltd.'s Jiangxi Phase II Project

2025-09-29

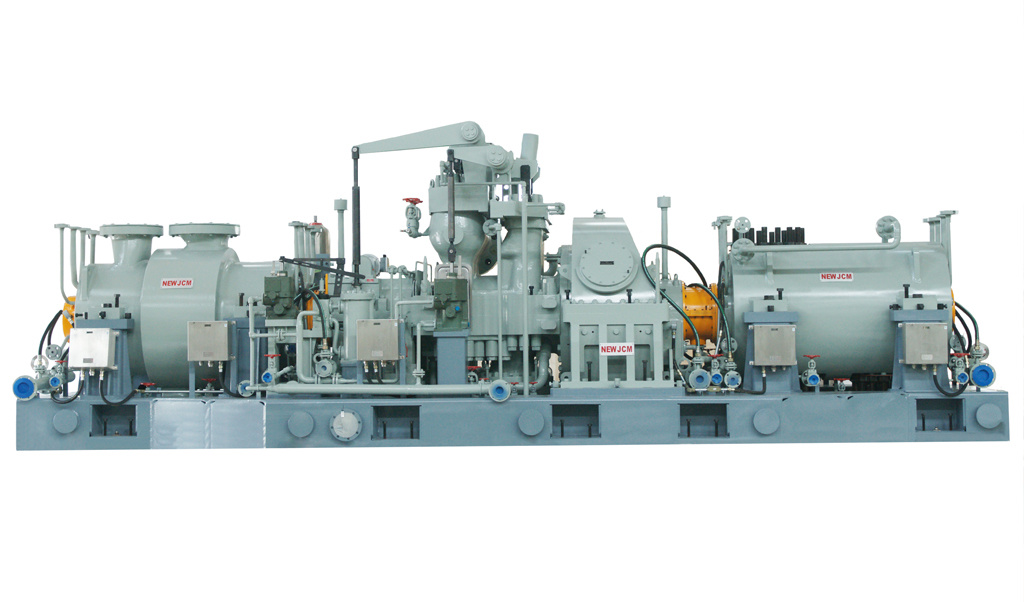

Recent exciting news from China’s chemical industry: Xinlianxin Chemical Industry Group’s Jiangxi Phase II project has been successfully started up. The synthesis gas compressor unit for the 800,000-ton-per-year synthetic ammonia unit, independently developed and manufactured by NEW JCM, achieved successful operation in its first trial. Its key energy efficiency indicators significantly outperform those of comparable imported equipment, ensuring the project’s timely production and capacity release.

Project Background: Fruit of a 10-Billion Investment,A Milestone Achievement

On September 23, Xinlianxin Group held a ceremony at its Jiangxi base to celebrate the successful startup. With the smooth production of qualified products, the Phase II project, with a total investment of RMB 10 billion, has achieved a one-time successful launch. This not only marks a major victory in Xinlianxin’s “Two Major Battles in Three Years” initiative but also represents a significant milestone in the group’s development history.

Another Success in Cooperation: Customized Equipment & Full-Cycle Support

This is not the first collaboration between NEW JCM and Xinlianxin. The two have previously partnered on 10 core equipment units for Xinlianxin’s bases in Henan, Xinjiang, Guangxi, and Jiangxi, earning high recognition from the group and project stakeholders.

As the core equipment supplier for the Jiangxi Phase II project, NEW JCM tailored the compressor unit to meet production requirements with high standards and reliability.

During the project construction and debugging phases, the NEW JCM team adhered to a rigorous and responsible approach—from pre-delivery inspections to on-site installation guidance and integrated system debugging—always aiming for “zero faults and high efficiency” to ensure perfect compatibility between the equipment and the overall project. The compressor set achieved successful operation in its first trial, with all parameters meeting design standards, providing solid equipment support for the stable operation of the synthetic ammonia unit and demonstrating internationally advanced technical capabilities. This successful cooperation further strengthens NEW JCM’s market position in the chemical equipment sector.

Technology & Breakthroughs: Twenty Years of Dedication, Leading Turbine Equipment

With 20 years of deep cultivation in the turbomachinery industry, NEW JCM has built a full-industry-chain system of "Technology R&D – Equipment Manufacturing – Engineering Services." In the field of high-end equipment manufacturing in China, it holds a significant advantage in the centrifugal compressors for synthetic ammonia , with a domestic market share exceeding 70%. To date, 26 units of synthetic ammonia compressors-turbines with an annual capacity of 600,000 tons or more have been delivered, and 27 units of urea carbon dioxide compressors-turbines with an annual capacity of 800,000 tons or more have been delivered, forming high technical barriers and strong customer loyalty. It is one of the few suppliers worldwide that can simultaneously provide carbon dioxide and syngas compressors.

Over the years, NEW JCM has continuously broken new ground in centrifugal compressor technology, achieving multiple remarkable “first-of-its-kind” accomplishments in compressor-turbine unit for synthetic ammonia syngas and urea carbon dioxide applications. Starting from a 130,000-ton synthetic ammonia syngas compressor unit, NEW JCM successively developed China’s first 450,000-ton and 750,000-ton synthetic ammonia syngas compressor-turbine sets, and has now reached the milestone of a 1-million-ton unit, showcasing the exceptional performance of Chinese manufacturing. The company’s technical level in syngas compressor unit is now in the global first tier, with a leading domestic market share.

Future Development: Coordinated Innovation and Shared Growth

NEW JCM self-developed “NEWJCM” brand centrifugal compressors, industrial steam turbines, and complete sets of equipment are critical for the production of synthetic ammonia, urea, caustic soda, methanol, ethylene glycol, and amino acids globally.

Looking ahead, NEW JCM will continue to leverage its strong technical expertise and increase R&D investment, committed to providing high-performance, energy-efficient, and environmentally friendly compressor solutions for the global chemical industry. As partners like Xinlianxin Chemical Industry Group advance toward their goal of building “RMB 10 billion bases,” NEW JCM will fully utilize its advantages in key equipment supply and technical services to offer comprehensive support. Together with its partners, NEW JCM will drive high-quality development in the chemical industry and contribute to the prosperity of the national real economy.

Recommend News

NEW JCM will be showcased at the 2025 ADIPEC

2025-11-03