Green Hydrogen-Ammonia-Methanol Integrated Project

2025-08-08

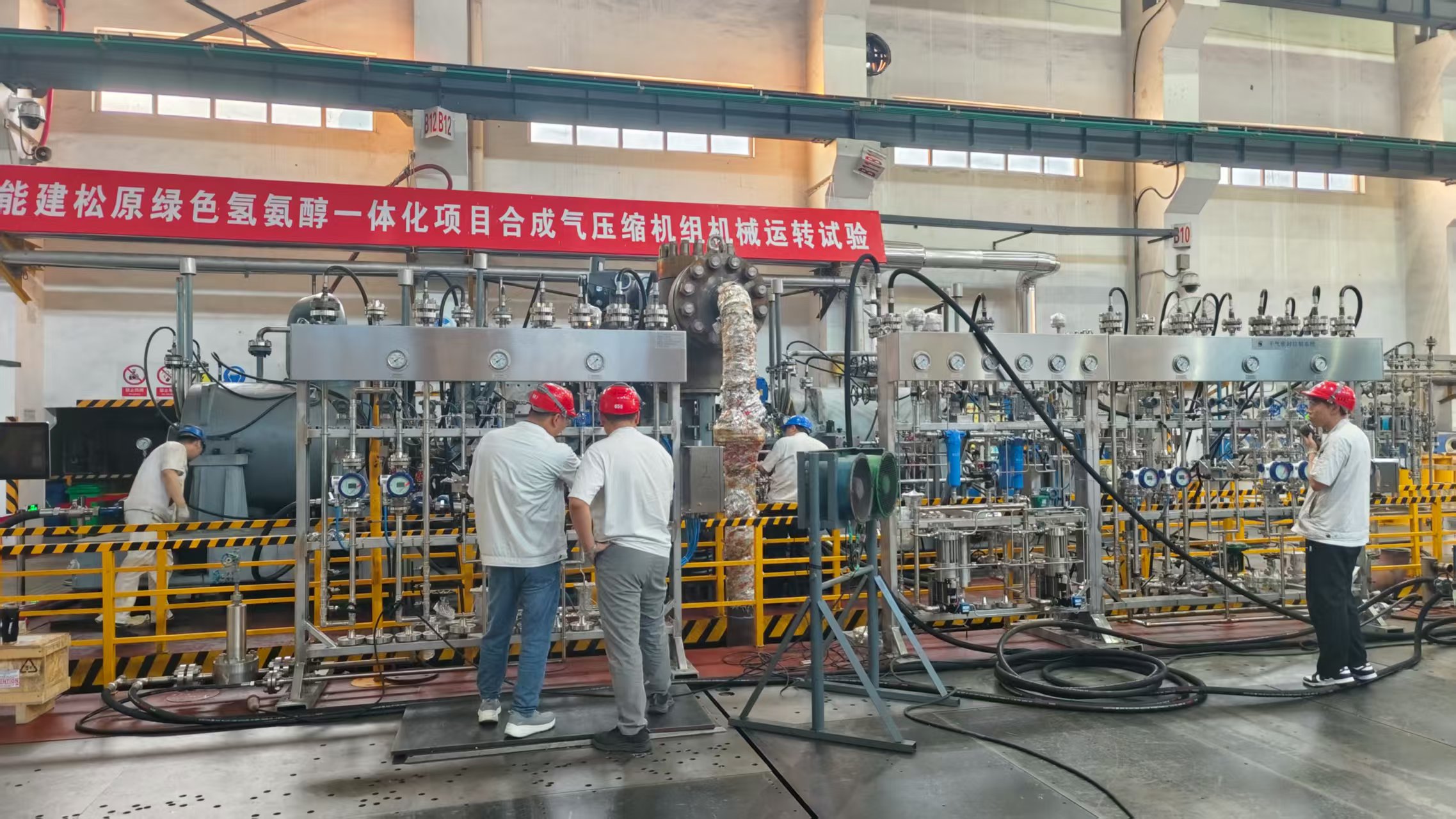

NEW JCM's green hydrogen-ammonia syngas compressor unit is set to commence operation in the world's largest green hydrogen-ammonia-methanol integrated project. Featuring a high-efficiency, energy-saving design and meeting ultra-long cycle stable operation requirements, this unit not only provides a solid technical foundation for the project but also signifies the company's internationally advanced technical capabilities in the core equipment domain of the green hydrogen industrial chain!

Project Background

As the flagship project among the first batch of Green and Low-carbon Advanced Technology Demonstration Projects approved by China's National Development and Reform Commission (NDRC), the China Energy Engineering Group Songyuan Hydrogen Industrial Park project – an integrated facility producing 110,000 tons of green hydrogen and 600,000 tons of green ammonia/methanol annually – achieves deep integration of green energy and the chemical industry through wind-solar power generation for green hydrogen production and subsequent synthesis of green ammonia/methanol. Upon operation, it is projected to reduce annual CO₂ emissions by 650,000 tons, positioning itself as a leading domestic production base for green energy and chemical products. The syngas compressor unit is the core equipment linking green hydrogen production with ammonia/methanol synthesis, undertaking the critical task of pressurizing the feedstock gas to the synthesis reaction pressure. This unit faces significant challenges: the special compression medium (containing hydrogen), complex and variable operating conditions, extremely high continuous operation requirements (no less than 5 years), coupled with the project's immense scale, high degree of technological integration, and tight construction schedule.

Technological Breakthrough, Forging the Cornerstone of Green Energy

Leveraging profound technical expertise and continuous innovation investment, NEW JCM successfully overcame core challenges including efficient aerodynamic design for syngas (hydrogen-containing) media, long-cycle operational reliability under extreme conditions, and rotor dynamic stability of large-scale units. The syngas compressor unit employs a customized, high-efficiency, energy-saving design that ensures processing capacity and compression efficiency while significantly optimizing energy consumption levels.

Crucially, this unit is rigorously designed and manufactured to meet stringent industrial-grade standards, guaranteeing continuous stable operation for over 5 years and a total design lifespan of no less than 20 years. Its key technical parameters and performance indicators reach internationally advanced levels, ensuring powerful and reliable core power throughout the entire project lifecycle.

The successful commissioning of this critical equipment not only provides core equipment assurance for the smooth implementation of China Energy Engineering Group Songyuan – China's first large-scale integrated green hydrogen-ammonia-methanol co-production project – but also marks a milestone breakthrough for NEW JCM in the independent design and manufacturing capabilities of core equipment for the green hydrogen industrial chain. It provides a powerful "domestically produced core" for the green and low-carbon transformation of China's energy and chemical industry.

Empowering green transformation, contributing“NEW JCM Strength”

Moving forward, NEW JCM will continue to uphold the principles of "Innovation-Driven, Pursuing Excellence, Customer First," relentlessly advancing cutting-edge technologies, and continuously promoting product upgrades and solution optimization. We are committed to supporting our customers' transformation and upgrading in green energy, high-end chemicals, and other fields with more efficient, reliable, and energy-saving compressor units and system services, contributing solid NEW JCM strength to the optimization of the global energy structure and sustainable development!

Recommend News

NEW JCM will be showcased at the 2025 ADIPEC

2025-11-03