Shaanxi Longhua’s 500,000 Tons/Year Synthetic Ammonia Plant Achieves Full-Load Operation with Industry-Leading Performance Indicators

2025-05-07

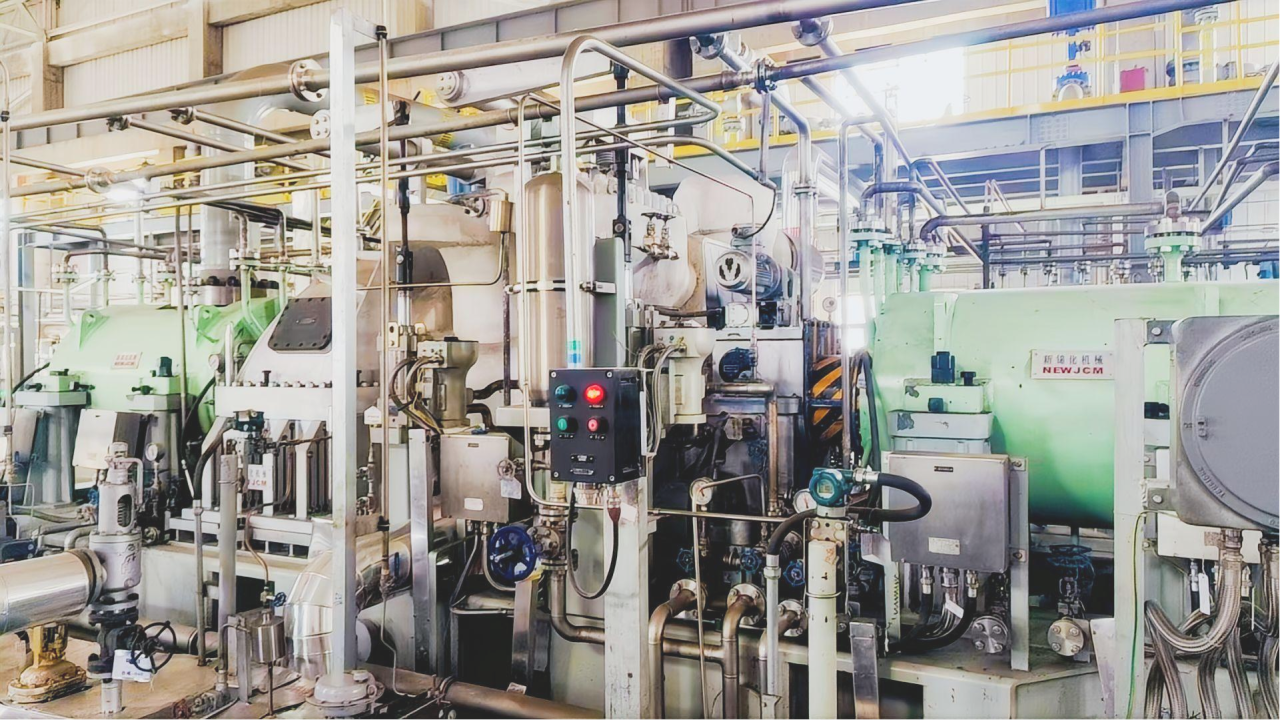

Recently, good news came from Shaanxi Longhua Coal Chemical Company, a subsidiary of Shaanxi Longhua Group Coal Industry Technology Development Co., Ltd plant with an annual output of 500,000 tons has achieved 100% full-load stable operation with outstanding performance in key production indicators. NEW JCM Group’s subsidiary, Jinzhou NEWJCM Machinery Manufacture Co., Ltd., provided the project with the synthesis gas compressor for the 500,000 tons/year ammonia plant, the CO₂ compressor for the 800,000 tons/year urea unit, as well as the steam turbines for the three core units (synthesis gas, CO₂, and ammonia refrigeration compressor). Since the entire unit was successfully commissioned in one go in December 2023, it has been operating with stability and high efficiency, with all parameters exceeding design expectations.

Since its successful commissioning and operation in August 2024, the synthetic ammonia system has undergone continuous optimization and adjustment, and has now successfully achieved full-load operation, reaching an ammonia production rate of 101 tons per hour. All performance indicators exceed the design values. Under full-load conditions, the ammonia synthesis tower exhibits high reaction efficiency, with a temperature rise of over 280°C between the inlet and outlet, and a net ammonia content of over 19%. The stable full-load operation of this project marks a new milestone in the development of domestically produced large-scale ammonia synthesis technologies.

Project Overview

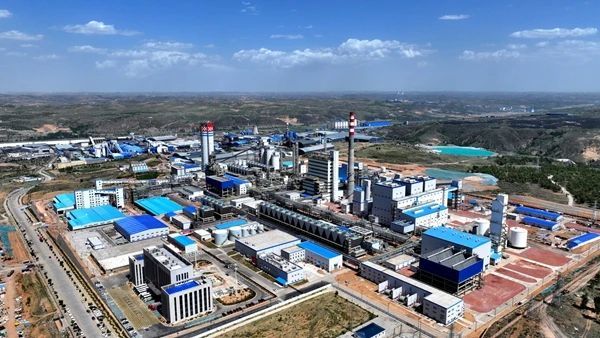

Shaanxi Longhua Group Coal Industry Technology Development Co., Ltd., a wholly-owned subsidiary of Sunjiacha Longhua Mining Co., Ltd. under Shaanxi Coal and Chemical Industry Group, is located in the Yanjia Tower area of the Lantan Industrial Park in Shenmu City. Since its establishment in December 2012, the company has been committed to the clean and efficient utilization of coal. Its coal classification and grading clean and efficient comprehensive utilization project is a key project in both Shaanxi Province and Yulin City’s “14th Five-Year Plan”. It also underscores the company's firm commitment to promoting green development in the industry.

With a total investment of 7.07 billion yuan, the project covers more than 1,000 mu (approx. 165 acres) and is located in the Yanjia Tower area of the Lantan Industrial Park in Shenmu City. The project is divided into two phases. Phase I includes a 500,000 tons/year synthetic ammonia unit, an 800,000 tons/year urea unit, a 60,000 tons/year melamine unit, and associated utilities. Phase II will include a 1 million tons/year acetic acid unit. Once completed, the project is expected to generate an annual output value of about 11 billion yuan, pay 1.13 billion yuan in taxes annually, and create over 1,200 jobs. The project adopts advanced technologies such as clean coal gasification, ammonia synthesis, low-temperature methanol rectisol, sulfur recovery, isothermal shift conversion, and liquid nitrogen rectisol. Using synthetic ammonia as the raw material, it produces urea and melamine, making it one of the most advanced urea-melamine co-production projects in China.

Following the model of “clean production, circular development, and park-based implementation”, the project extends the industrial chain with new technologies. It features the largest single-unit urea plant in China and is the first time the EPC-mode patented urea technology of Wuhuan Engineering Company has been transferred. It also includes the country’s first melamine unit using European fifth-generation technology. Upon completion, the project will produce 500,000 tons/year of synthetic ammonia, 800,000 tons/year of urea, and 60,000 tons/year of melamine, significantly promoting the extension, enhancement, and strengthening of the coal industry chain and increasing the added value of coal resources. This will be a major step in realizing clean, efficient, high-end, and diversified utilization of coal.

Recommend News

NEW JCM will be showcased at the 2025 ADIPEC

2025-11-03